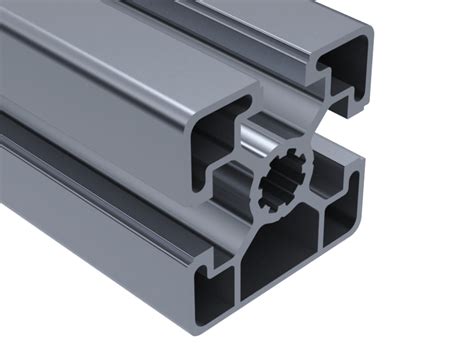

T-slot aluminum profiles are widely used in various industries due to their versatility, ease of use, and durability. These profiles are made from high-quality aluminum alloy and are designed with a T-shaped slot that allows for easy connection to other components such as motors, sensors, and controllers.

Applications of T-Slot Aluminum Profiles

T-slot aluminum profiles can be used in various applications, including:

- Exhibits and Displays: T-slot aluminum profiles can be used to create customized exhibits and displays for trade shows, museums, and retail stores. The profiles can be used to construct shelves, hanging systems, and other display components.

- Ergonomic Workstations: T-slot aluminum profiles can be used to create ergonomic workstations that can be easily adjusted to fit the needs of the user. The profiles can be used to construct adjustable height workstations, tool racks, and other ergonomic components.

- Robotics and Prototyping: T-slot aluminum profiles are commonly used in the construction of robotic systems and prototyping. The profiles can be used to construct frames, linear motion systems, and other components for robots and other automated systems.

- Structural Framing: T-slot aluminum profiles can be used to construct lightweight structural frames for buildings, enclosures, and other structures. The profiles are easy to assemble and can be easily modified or expanded as needed.

Types and Sizes of T-Slot Aluminum Profiles

T-slot aluminum profiles are available in various types and sizes to meet the needs of different applications. Some of the most common types and sizes include:

- Fractional Series: Fractional T-slot aluminum profiles are the most common type and are available in sizes ranging from 1 inch x 1 inch to 8 inches x 8 inches.

- Metric Series: Metric T-slot aluminum profiles are designed for use in European applications and are available in sizes ranging from 20 mm x 20 mm to 120 mm x 120 mm.

- Slim Series: Slim T-slot aluminum profiles are designed for applications where space is limited. These profiles are typically used in electronics, robotics, and other high-tech applications.

- Heavy-Duty Series: Heavy-duty T-slot aluminum profiles are designed for applications where extra strength and durability are required. These profiles are typically used in heavy machinery, automotive, and aerospace applications.

- Hybrid Series: Hybrid T-slot aluminum profiles are a combination of fractional and metric profiles, allowing for greater flexibility and versatility in design.

Finishing Options for T-Slot Aluminum Profiles

T-slot aluminum profiles are available with various finishes and surface treatments to enhance their appearance, durability, and corrosion resistance. Some of the most common finishing options include:

- Powder Coating: Powder coating is a dry powder that is applied to the surface of the aluminum and then cured in an oven.

- Anodizing: Anodizing is an electrochemical process that coats the surface of the aluminum with a protective oxide layer.

- Brushed Finish: A brushed finish involves using abrasive pads to create a uniform pattern of fine scratches on the surface of the aluminum.

- Polished Finish: Polishing involves buffing the surface of the aluminum with abrasive compounds to create a smooth and shiny finish.

- Matte Finish: A matte finish is a non-glossy finish that can create a modern and sophisticated look.

- Textured Finish: Textured finishes can create a unique appearance and texture on the surface of the aluminum.

Protective Coatings for T-Slot Aluminum Profiles

T-slot aluminum profiles are available with protective coatings to prevent corrosion, wear, and scratching. Some of the most common protective coatings include:

- Clear Coat: A clear coat is a protective layer that is applied on top of the finish to protect the aluminum from oxidation, wear, and scratching.

- Sealant: A sealant is a protective layer that is applied to the joints and connections of T-slot aluminum structures to prevent moisture and debris from entering and causing corrosion or damage.

Overall, T-slot aluminum profiles offer a wide range of customization options to meet the specific requirements and aesthetics of various applications.