Kamet delivers industrial-quality RTD sensors specifically designed for use in the slots between the stator windings of motors and generators. Our Stator Slot RTD sensor has sensors along most of its length, providing continuous average temperature readings across a wide area. This design allows for very accurate average temperature monitoring and ensures no localized hot-spots are missed.

Benefits of Stator Slot RTD Sensors

Kamet's Stator Slot RTD's are already key components in the hydroelectric industry, wind turbines, and other generators. However, accurate and consistent measurement of thermal shifts in stator windings is highly relevant throughout all industries where electric motors are in use. As such, Kamet strives to bring these listed benefits of Stator Slot RTD sensors to the attention of a broad range of industries, facilitating companies in keeping up with current electric motor and generator development trends.

Stator slot temperature readings can be used to:

- Prevent overheating, increasing longevity

- Ensure precise and timely cooling, improving motor efficiency

- Provide early indication of core component failure or incorrect voltage (e.g., temperatures continue to increase despite cooling)

- Protective functionality:

- Significant cost savings in the long term (prevents unnecessary damage to insulation or mechanical elements)

- A considerable contribution to safety (e.g., during peak demand at a hydropower plant)

- Reliability, as the motor has less "downtime"

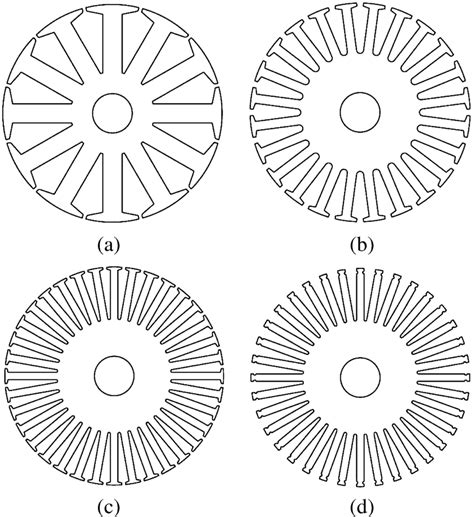

Stator Slot Sensors Design and Properties

Our sensors are designed with the following properties:

- Both flat and thin to fit between windings

- Usually made with wire-wound RTDs

- Sensors along the entire length

- Durable: resistant to shock, pressure, and vibration

- Bifiliar design to prevent measurement errors caused by induction voltage

- Withstand voltage of up to 3KV

- Maximum short-circuit current of 20mA

- High-temperature epoxy glass casing provides insulation class F or H (F=155°C, H=180°C)

- Specialized sheath materials (e.g., teflon) can increase operating temperature up to 250°C

- Single or dual elements

- Available in versions suited for hazardous environments (Atex and IECEx certification)

Kamet's Product Range

Kamet offers a range of products, including:

- Stator slot style Pt100 sensors in lengths of 100mm, commonly used

- Resistances: Pt1000, Pt500, and Pt200

- Lengths up to 500mm

- Diameters between 8-12mm

- A choice of lead wire materials: silver, nickel or tin plated copper wires in various AWG sizes

- Builds with 2, 3, or 4 lead wires and single or duplex elements

- Certified "intrinsically safe" and "increased safety" models for hazardous, explosive environments. The level of protection is certified in accordance with Directive 2014/34/UE (ATEX) for gases and dust.

Customization

This variety in specifications, combined with the dynamic needs of customers across a range of industrial environments, means that most of Kamet's stator slot RTD's are delivered as bespoke products. Our in-house specialists will be delighted to answer your queries and discuss your situation.

Kamet Quality and Service

At Kamet, we pride ourselves on our customer service. You can be certain of a response within 24 hours. Please note that there is a 3-4 week delivery time, depending on the chosen configuration and level of customization.

When you purchase a product from Kamet, you are guaranteed exceptional quality. All our parts and materials originate from Europe, USA, and/or Japan. We build and maintain close relations with our suppliers and are therefore well-positioned to provide our clients with the most accurate information about our products and the latest trends and developments.

By choosing Kamet's Stator Slot RTD sensors, you can be confident that you will receive a high-quality product designed to meet your specific needs. Our commitment to customer service and quality ensures that you will have a seamless experience from order to delivery.