In the development of cream, lotion, and emulsion products, understanding the size and stability of colloidal dispersions is crucial. This article will discuss the importance of dynamic light scattering (DLS) in analyzing these parameters.

Food and Beverage

In the food and beverage industry, DLS is used to analyze the particle size distribution and agglomeration behavior of emulsions. This information is essential in determining the texture, stability, and sensory characteristics of the final product. For example, understanding the particle size distribution of milk fat globules can help in formulating dairy products with improved texture and shelf life.

Material Science and Nanotechnology

In material science and nanotechnology, DLS is used to measure the size and stability of nanoparticles. This information is crucial in optimizing the properties of these particles for various applications. For instance, understanding the particle size distribution of nanoparticles can help in designing materials with enhanced mechanical strength, optical transparency, and thermal conductivity.

Environmental Monitoring

In environmental monitoring, DLS is used to analyze the size and stability of nanoparticles in water samples. This information is essential in assessing the impact of nanoparticles on ecosystems and human health. For example, understanding the particle size distribution of engineered nanoparticles can help in predicting their fate and transport in aquatic environments.

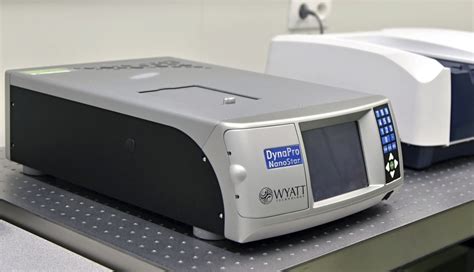

Our DLS Instrument

At Malvern Panalytical, we offer advanced DLS instruments designed to meet the diverse needs of researchers and industry experts. Our Zetasizer Advance product line combines precision, reliability, and user-friendly features to provide accurate and insightful data.

Key Features and Benefits

- Rapid and reliable particle size analysis with high precision

- Multi-angle dynamic light scattering (MADLS) technology for improved measurement range and resolution

- Simple and quick peak particle concentration measurement

- Ability to estimate average particle size from viscosity measurements

- Low sample volume requirements (minimum 3µL)

- Compatibility with a wide range of sample types, including high-concentration samples

Regulatory Compliance

Our DLS instruments comply with various regulatory standards, including ISO 13321 and ISO 22412. Our team is dedicated to providing expert support and guidance in the application of our technology.

NanoLab 3D: A Compact DLS Instrument for High-Concentration Samples

NanoLab 3D is a compact DLS instrument designed specifically for measuring particle size distributions in high-concentration samples. Unlike traditional DLS instruments, which require significant sample dilution to mitigate multiple scattering effects, NanoLab 3D uses patented 3D modulation technology to efficiently suppress these effects. This allows for accurate measurements of particles as small as 0.15nm and up to 5µm in diameter.

Key Features

- High-concentration sample measurement capabilities

- Cumulant and CORENN analysis for advanced particle size distribution characterization

- Microviscosimetry capability for estimating average particle size from viscosity measurements

- Sample volume requirements: 50µL-2µL (minimum 4µL)

- Temperature range: 4°C-90°C

- Time-dependent process monitoring capability

****, DLS is a powerful analytical technique that provides valuable insights into the size and stability of colloidal dispersions. Our Zetasizer Advance product line offers advanced features and capabilities to support researchers and industry experts in their pursuit of innovative materials and products. Whether you are working in the food and beverage industry, material science and nanotechnology, or environmental monitoring, our DLS instruments can help you achieve your goals.